PIPO MOTEURS, créateur de moteurs hautes performances depuis 1973

Moteurs

Compétition

Profitez de notre expérience de

multiple champion du monde

dans plusieurs disciplines

Moteurs

Hydrogène

Exploitez de nouvelles opportunités

grâce à nos moteurs hydrogène

haute performance

Prestations

complementaires

Concrétisez vos projets

les plus ambitieux avec nos

solutions sur mesure

Nos solutions pour répondre à vos besoins spécifiques

Besoin spécifique pour un moteur ou pièces sur mesure sans cahier des

charges défini

Ingénierie

Retro ingénierie

Conception

Bureau d’études

Cahier des charges défini par le client pour un moteur ou pièces sur mesure

Nos solutions pour répondre à vos besoins spécifiques

Pipo moteurs fait passer le moteur thermique à l’hydrogène

Pipo Moteurs a bâti sa réputation grâce à des partenariats de longue date avec des constructeurs de renom, tels que Ford, PSA, Hyundai et Bentley, avec lesquels elle a remporté à ce jour 13 titres mondiaux FIA (pilotes et constructeurs).

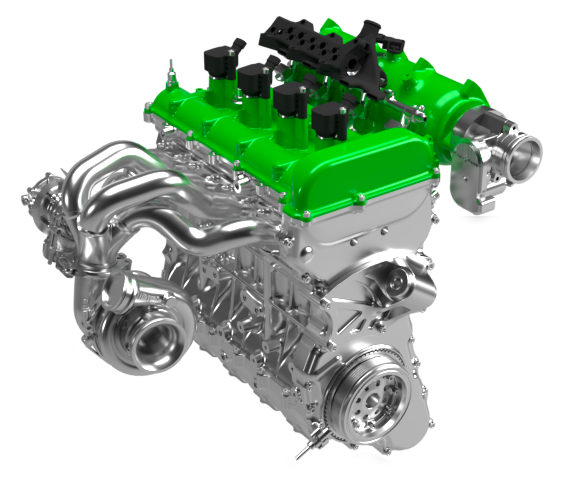

2016 a été une année charnière pour Pipo Moteurs. Seul acteur, indépendant de tout constructeur, la société se lance dans le développement de son propre moteur, un 4 cylindres turbo pour les Championnats de Rallycross et en 2020, d’un V8 biturbo qui fait forte impression dans le Championnat du monde d’Endurance (24 heures du Mans).

En affichant une forte capacité d’innovation et une véritable culture de la gagne, notre prochain défi est d’introduire le moteur à combustion interne à hydrogène dans les compétitions.

L’actualité pipo moteurs

Le RSD3 : RIST + SEPAG + DDD 2024

Le RSD3 : RIST + SEPAG + DDD, événement incontournable dans le domaine de l’#industrie sur le territoire du grand sud

𝗦𝗮𝗹𝗼𝗻 𝗛𝘆𝗩𝗼𝗹𝘂𝘁𝗶𝗼𝗻 𝟮𝟬𝟮𝟰 : 𝗨𝗻 𝗯𝗶𝗹𝗮𝗻 𝗽𝗼𝘀𝗶𝘁𝗶𝗳

𝗦𝗮𝗹𝗼𝗻 𝗛𝘆𝗩𝗼𝗹𝘂𝘁𝗶𝗼𝗻 𝟮𝟬𝟮𝟰 : 𝗨𝗻 𝗯𝗶𝗹𝗮𝗻 𝗽𝗼𝘀𝗶𝘁𝗶𝗳

Nous sommes ravis de partager avec vous le succès de notre participation au Salon HyVolution 2024

Moteur hydrogène : CRMT et Pipo Moteurs accélèrent

Moteur hydrogène : CRMT et Pipo Moteurs accélèrent

Abonnez-vous à notre page Linkedin

Et ne manquez pas nos dernières actualités…